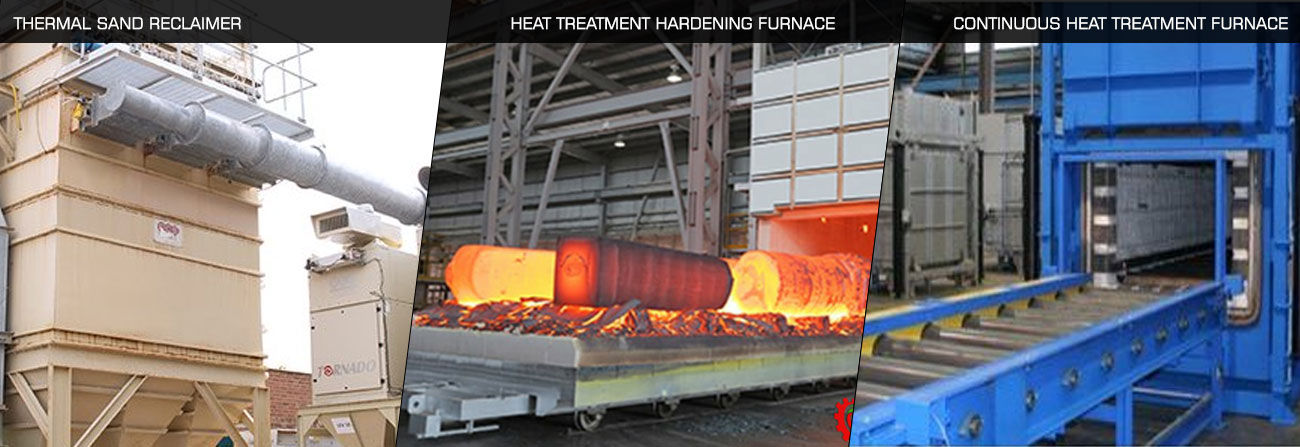

A trusted manufacturer of Furnace, Bogie Hearth Furnace, Aluminium Melting Furnace, Continuous Annealing Furnace, Normalizing Furnace, Fixed Hearth Furnace, Gas Fired Furnace, etc.

We, Mass Engineers, are a quality-centric manufacture and supplier of Normalising Annealing Furnace, Bogie Hearth Furnace, Fixed Hearth Furnace, Heat Treatment Furnaces, Decoating Furnaces, Vibraclaim, and so on. From us, customers can also avail the services like Mechanical Services and Calibration Services

at the best market rates. Our production unit consists of advanced

machines like Lathe Machines, Slotting Machine, Welding Machines, Radial

Drilling Machine, Magnetic Drill Machine, etc which help us to

accomplish the tasks in a systematic manner. Our team consists of highly

experienced production managers, maintenance managers, design manager,

and other skilled staff.

-

Solution Annealing Furnaces -

Continuous Annealing Furnace -

Heat Treatment Furnace -

Continuous Furnaces -

Continuous Roller Furnaces -

Rapid Quenching Furnaces -

Industrial Batch Oven -

Core Drying Oven -

Sand Vibra Claim -

Submersible Agitator -

Thermal Sand Reclamation -

Sand Dryer -

Biomedical Waste Incinerator -

Ewaste calciner -

Bogie Hearth Furnace

Our Team

Archana Pawar:

- She is the Managing Director of our company and holds an experience of 10 years in Heat Treatment Furnace Line.

- She has done M.B.A in Finance, D.B.M, P.G.D.C.A.

- She looks commercial order finalization, project planning & execution, as well as company system & policy PDCA from the root level.

- She has completed more than 200 projects and guides out purchase from commercial and project cost point of view.

- She has handled the overseas business project from the U.K., Nigeria, Mexico, South Africa, all Gulf countries, etc.

- Reviews the projects and coordinates with HOD of different departments.

- Import Export document compliance, Funds Planning, and Recovery.

- Site service management, planning in India and Overseas as well as planning of spares inventory.

- She also handles all the marketing activity including business promotions, advertising and web promotions.

- He is the Service and operation Manager of our enterprise and holds a Mechanical Engineer degree.

- He has an experience of 10 years experience in Project, Steel Foundry and Forging line.

- He has worked with many reputed companies namely

- Sara Sae Pvt Ltd as Maintenance Head, Forging MNC Company

- BOFCO Engineers as a Project Engineer, Heat Treatment Furnace Manufacturer

- He is given the following responsibilities in our company

- To make sure that the products are well designed and installed.

- He provides technical guidance to the professionals for predictive and preventive maintenance programs.

- Organize regular meetings of teams and their activities.

- Manufacturing, Erection and commissioning of the furnace on drawing and layout, pipeline connections, cooling tower, making arrangement for the rail line, oil pump heating unit, oil pipeline connections, etc.

- Experience of having control on-site control of 03 T " Time, Team and Trial of machines.

- Fire fighting, troubleshooting and site situation.

Our Speciality

Our company is established in Kupwad MIDC (Plot No E-38) over the area of 30000 sq ft working area in Sangli area of Maharashtra India. We are specialized in designing and manufacturing of the following products:

|

Furnace |

Slug Annealing Furnace |

|

Bogie Hearth Furnace |

Mesh Belt Furnace |

|

Fixed Hearth Furnace |

Salt Oven |

|

Gas Fired Furnace |

Conveyor Supplier |

|

Dual Fired Heat Treatment Furnace |

Preheaters |

|

Heat Treatment Furnace |

Continuous Hard Tempering Normalising Furnace |

|

Rapid Quenching Furnace |

Thermal Sand Reclamation Plant |

|

Hardening Tempering Normalising Furnace |

Sand Reclamation Unit |

|

Mould Oven |

Ladle Preheater |

|

Oven |

Sand Drier |

Quality Assurance Plan

- The procured raw materials are purchased from the certified entities of the market.

- Before selling Sand Reclamation Unit, Thermal Sand Reclamation Plant, Continuous Hard Tempering Normalising Furnace, Preheaters, or any other manufactured product various tests are conducted by us which includes welding test, full fuel test, a dimensional test of fabrication.

- Full hot trial for Small furnaces and dry trial for large furnaces

Our Abilities

- We design efficient Combustion Equipment, Thermal Profiles, and Electrical Circuitry.

- We design and manufacture various types of burners, furnaces, Ladle Pre-heaters, Mould, Driers, Core driers, and Incinerators.

- Our company is also associated with equipment structural and thermal designing of related components.

- Developing required programs for PLC integrated with the automation system.

- 3D modeling on software

- Programming on Inventor of auto-desk.

|

MASS ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |